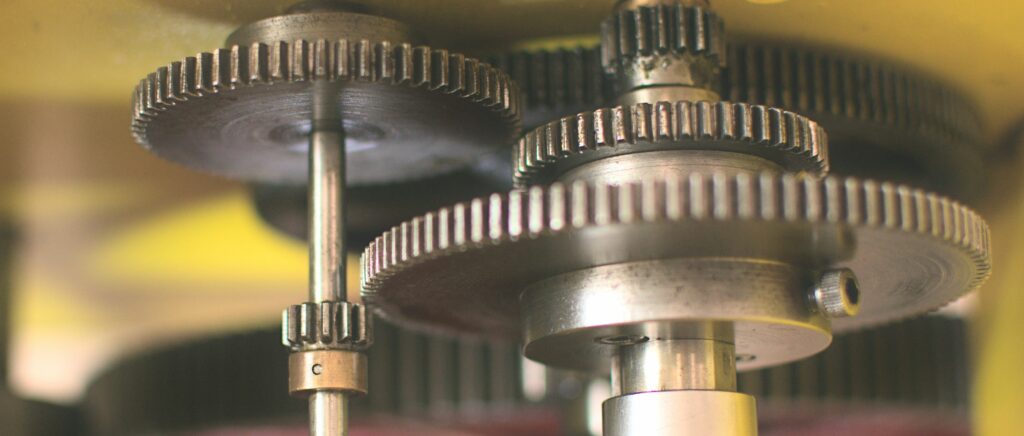

All engines running!

After a long trip from the sunny coast of Perth to the not-so-sunny Upper Rhine Plain, followed by

a restoration work by Sebastian and Dan, our Griggs Apparatus is back to life!

After some calibration experiments, we were ready to start our first rock-deformation experiment in

Heidelberg.

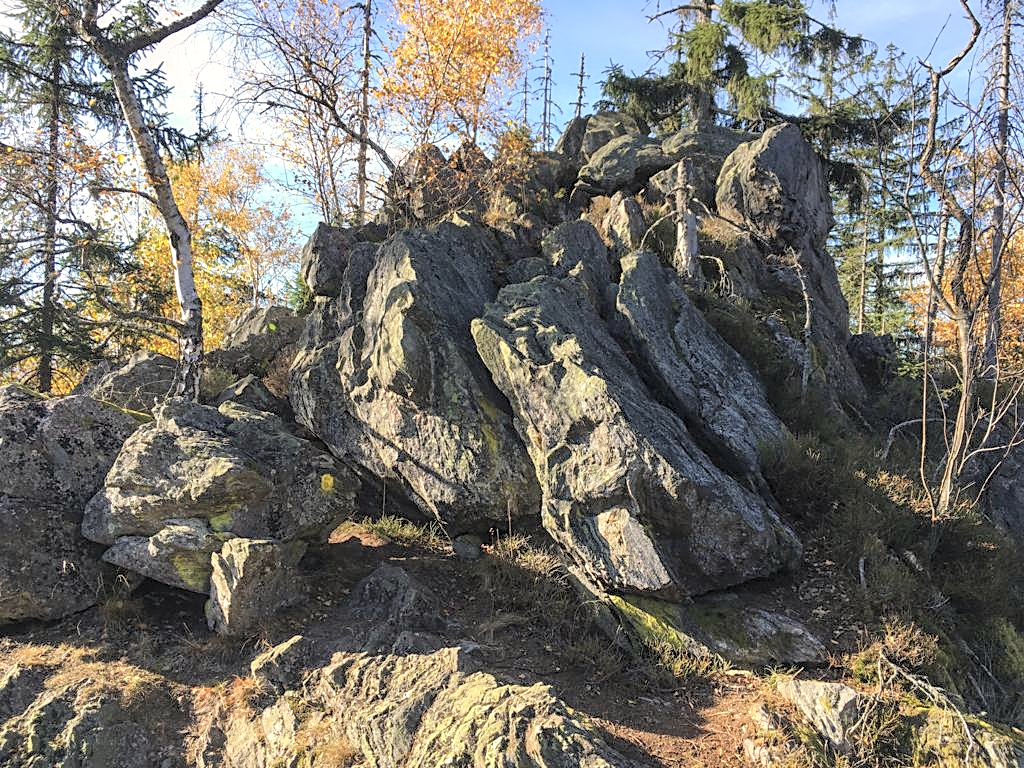

Our first sample was a quartzite I’ve collected from the Osser Mountain, located at the border

between the Bavarian and Bohemian forests. Quartz (the main mineral in a quartzite) is one of the

most common minerals in the Earth’s continental crust. Thus, by studying how these rocks behave

at conditions of the Earth’s crust might help us to understand large-scale processes occurring in this

region, such as earthquakes. The first question we want to answer with our experiments is how the

arrangement of crystals in these quartzites (microstructure) influence its strength, that is, how much

load it supports before it breaks.

We started preparing the experiments by drilling a small cylinder from a slab of the quartzite. We

then prepare our deformation assembly by putting together the sample, the pistons (hard material

that squeezes the sample) and the confining media (soft material that keeps the sample under

hydrostatic conditions). Because our first test was at environmental temperature, we could come up

with unconventional solutions for our experimental assembly. For example, we used paraffin wax (a

candle) instead of lead as the confining media. Wax is safer and more environmentally friendly than

lead, and comes with the unexpected bonus of leaving our lab with a smell of vanilla. Win-win.

Figure 1: Quartzites from the Osser Mountain

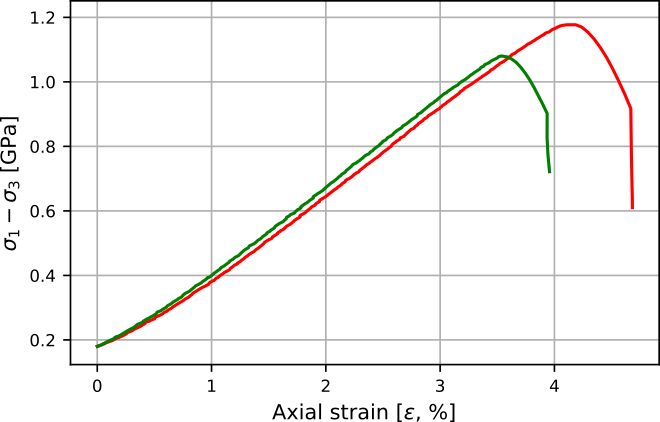

The experiments were performed by pressing the pistons against the sample at a constant

strain(displacement) rate and measuring the stress (load over the sample’s cross-sectional area)

supported by the sample. As the sample gets squeezed, we monitor the stress using a load cell and

the strain using a linear displacement sensor. The experiments were conducted until the sample

fails, which can be noticed by a sudden drop in stress and by a loud blow, which is slightly

worrying when you hear it for the first time. The graph below shows the mechanical behaviour of

two samples deformed experimentally at the same conditions but with different starting

microstructures (green and red curves). We can see that, by changing the initial microstructure, the

samples have contrasting strengths.

Our next steps will be focused on how the pressure and temperature

conditions of the Earth’s crust affects these results and on using electron microscopy to identify

which microstructural features influence the strength of quartz-dominated rocks.

We might also try experimenting with new candle scents as well…