- Griggs Rig

- Piston Cylinder

- Cold seal pressure vessels

- 1 atm gas-mixing furnaces

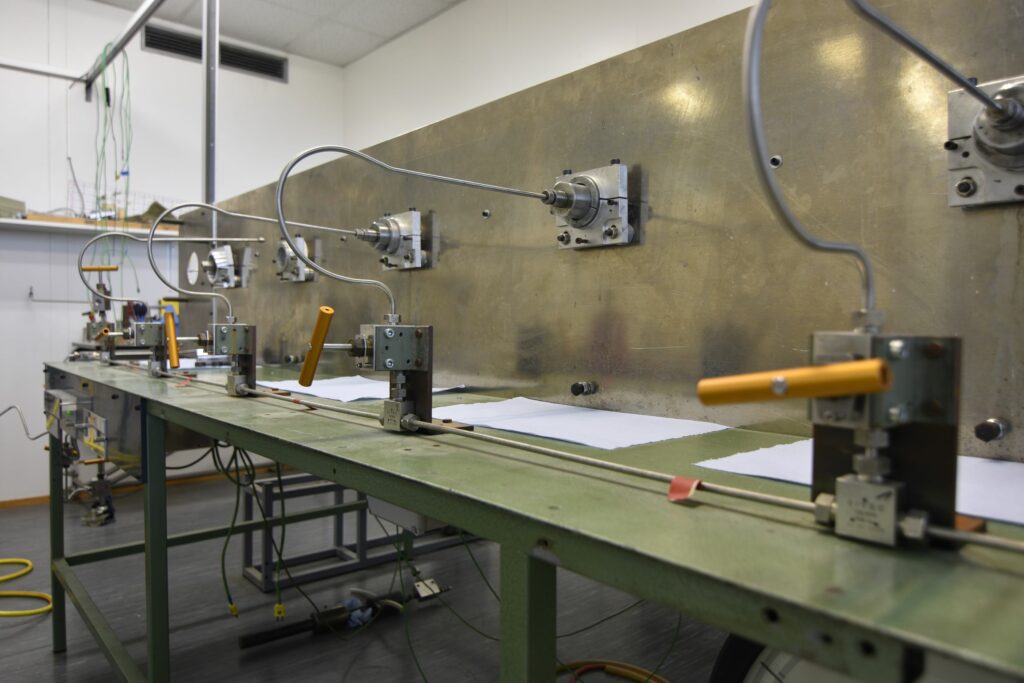

Griggs Rig

The “Griggs Rig” is a high pressure-temperature internally heated solid medium deformation apparatus, suitable for smaller samples. The machine is derived from original design (Tullis&Tullis, 1986), but additionally equipped with an end-load piston coupled to the confining pressure system.

Uniaxial and shear experiments can be performed.

Confining Pressure range: 0.4 – 2 GPa

Max. Principal Stress: 4.5 GPa

Max. Temperature: ca 1200°C (internally cooled Pressure vessels)

Sample Volume:

uniaxial: 6.6 mm diameter, 18 mm length

shear: slices at usually 45° angle and 1-2 mm thickness within uniaxial sample volume (6.6 mm diameter) confined by alumina forcing blocks

Confining medium: NaCl (above 700°C) or KCl (below 700°C) salt cells (no molten salt experiments are planned now)

An upgrade of one Griggs rig with acoustic emission sensors is ongoing.

We thank Allison Ord, Bruce Hobbs and Katy Evans (Curtin University) for the Griggs Rigs available in our lab. Our second Griggs-Rig is still under reconstruction.

Piston cylinder apparatus

The piston cylinder apparatus is a high pressure-temperature internally heated solid medium device used for petrological experiments (phase-transition, reactions, melting). We use a “Boyd & England” type endloaded piston-cylinder with a 12.7 mm (1/2”) piston bore. We use NaCl and NaCl-pyrex-MgO/BN assemblies with straight graphite or steel furnaces and commonly K- and S-type thermocouples.

Pressure range: 0.5 – 4 GPa

Temperature range: up to 1800°C

Piston ram: 80 tons

End-load ram: 250 tons

Assembly: NaCl, NaCl-Pyrex-MgO/BN, Talc-Pyrex-Al2O3/BN

Sample capacity: Up to three 2.3mm capsules or single 4mm capsule

Cold Seal Pressure Vessels

“Cold Seals” are externally heated pressure devices that are operated with gas/fluid confining medium. Our laboratory is presently equipped with six vessels employing a “cold-seal” design.

Pressure: up to 600 Mpa (300MPa at T > 750°C)

Pressure medium: H2O

Temperature up to 900 °C

Recommended maximum capsule size: 40 x 5 mm

One-Atmosphere Gas Mixing Furnaces

In addition to high temperature box furnaces, we use two vertical gas mixing furnaces for heating at controlled oxygen fugacities. They allow experiments and the synthesis of starting materials over a wide range of redox conditions. The gas atmosphere can be adjusted using CO2 – CO mixtures at temperatures up to 1100°C to simulate reducing or moderately oxidizing conditions.

Sample Material and Assembly preparation

We are equipped with all necessary equipment to manufacture our assemblies and staring materials, next door to the experimental labs:

– 25t Hydraulic Press (assembly parts, rock crushing)

– Pillar drilling machine (also used for water-cooled coring of samples)

– Lathe (assembly parts, equipment modifications)

– Welders (fine-welder (PUK), gas-welders)

– Precision slow-saw

– High-precision Diamond wire saw equipped with goniometer (up to 5x5x3cm sample size and 0.15 – 0.3 mm cutting-wire diameter)

– Chemistry preparation lab